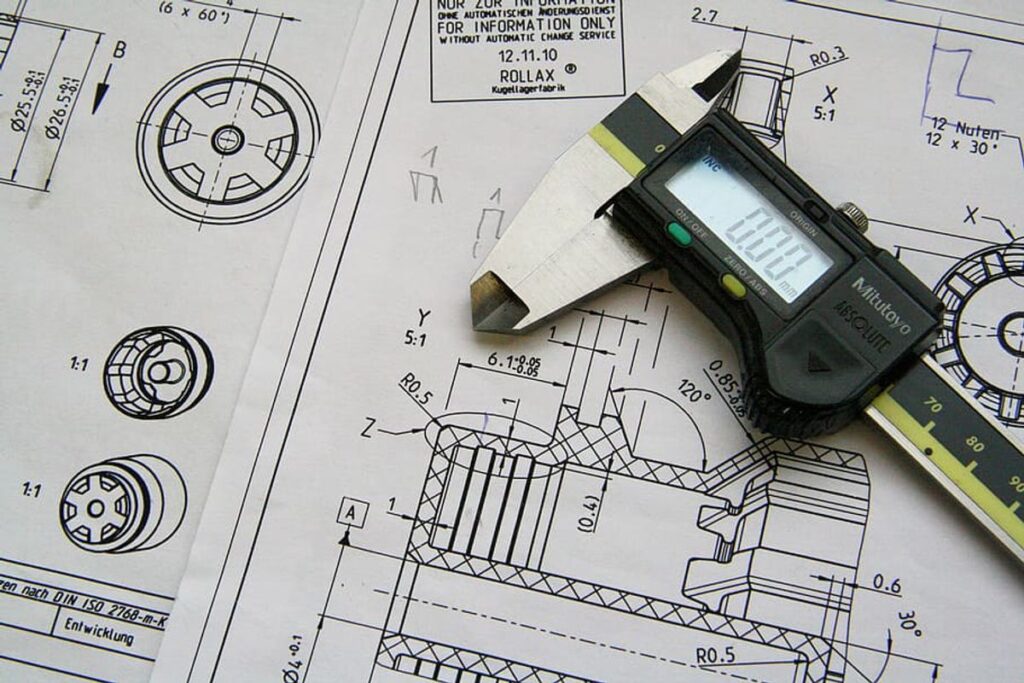

Precision and accuracy are critical in the field of woodworking and millwork manufacturing. Mastering the use of precise measuring tools is essential for ensuring high-quality outcomes in projects. In this article, we will explore the latest segment height measurement tools and discuss the importance of precision in woodworking.

Key Takeaways

- Accurate measuring tools like laser measures and tape measures are essential for different types of measurements in woodworking and millwork manufacturing.

- Cross-checking dimensions with cutting-edge software enhances precision in millwork estimation and quantity takeoff processes.

- Deltek Vantagepoint 6.5 offers enhancements in measuring tools, prototyping, production, and repair for efficient woodworking projects.

- 3D visualization tools and automation using specialized tools like high-end sales configurators are revolutionizing woodworking estimation processes.

- Precision and accuracy in woodworking manufacturing ensure projects are executed within budget and time constraints, preventing material shortages and excesses.

Accurate Measuring Tools

Laser Measures

In the realm of precision measurement, laser measures stand out for their ability to quickly and accurately gauge distances, especially in long spans and challenging locations. These devices have become indispensable in ensuring that every cut and join in woodworking and millwork is executed with exactitude.

Laser measures offer several advantages:

- Ease of use: With a simple point-and-click mechanism, measurements can be taken single-handedly.

- Versatility: They can measure both indoor and outdoor spaces with minimal interference.

- Data storage: Many models can store multiple measurements, facilitating efficient workflow.

Ensuring that measurements are accurate from the outset is critical to the success of any project. Laser measures contribute significantly to this by eliminating the guesswork and potential for human error.

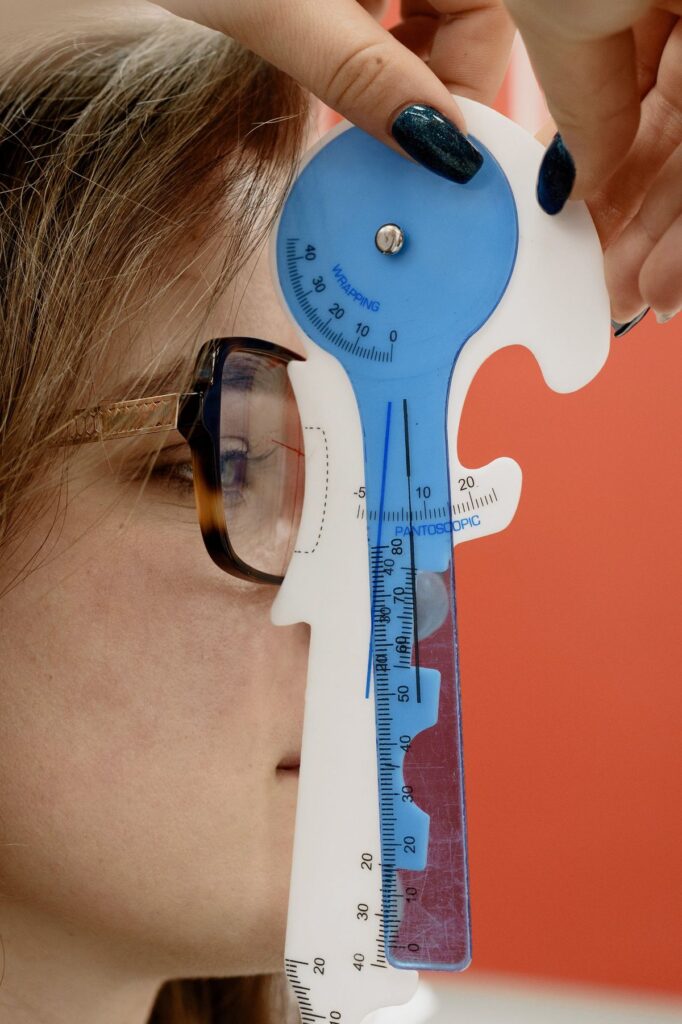

Accurate PD and SH measurements are crucial for prescription eyewear and PPE. Optigrid revolutionizes optical measurements, ensuring precise fit and vision correction. Simplified process enhances safety and compliance. The precision offered by laser measures aligns with the innovative strides seen in fields such as optical measurements, where tools like Optigrid have transformed the landscape by providing accurate PD and SH measurements that are essential for the correct fitting of prescription eyewear and personal protective equipment.

Tape Measures

In the realm of precision woodworking, the humble tape measure remains a cornerstone among measurement tools. Its simplicity and portability make it the go-to for quick, on-the-spot measurements. For tasks that require measuring shorter distances, a high-quality tape measure can provide the accuracy needed without the complexity of more advanced tools.

While laser measures and digital tools are gaining popularity, the tactile feedback and direct reading from a tape measure are irreplaceable for many craftsmen.

Tape measures come in various lengths and styles, each suited for different scenarios. Here’s a quick rundown of common types:

- Standard Tape Measures: Typically up to 25 feet, used for most woodworking projects.

- Long Tape Measures: Can extend up to 100 feet for larger sites.

- Keychain Tape Measures: Compact and handy for quick, small-scale measurements.

To ensure the reliability of measurements, especially in video analysis for calibration, it’s not uncommon to use multiple tape measures. This approach accommodates both left and right-handed users, preventing obstructions in the camera’s view and maintaining the integrity of the data collected.

Levels and Plumb Lines

Ensuring that structures are perfectly vertical and horizontal is crucial in woodworking and millwork manufacturing. Levels and plumb lines are indispensable tools for verifying alignment and balance. A level uses a liquid-filled vial with an air bubble to determine the true horizontal, while a plumb line, relying on gravity, indicates the vertical.

- Start with a level to check flat surfaces and ensure they are perfectly horizontal.

- Use a plumb line to establish vertical lines, especially in the construction of walls or installation of cabinetry.

- Regularly cross-check measurements with levels and plumb lines to account for any shifts or settling of materials over time.

Accuracy in these measurements is not just about aesthetics; it’s about structural integrity and the longevity of the project. Even a slight deviation can lead to significant issues down the line. Therefore, it’s essential to use these tools methodically and consistently throughout the project.

Angle Measuring Tools

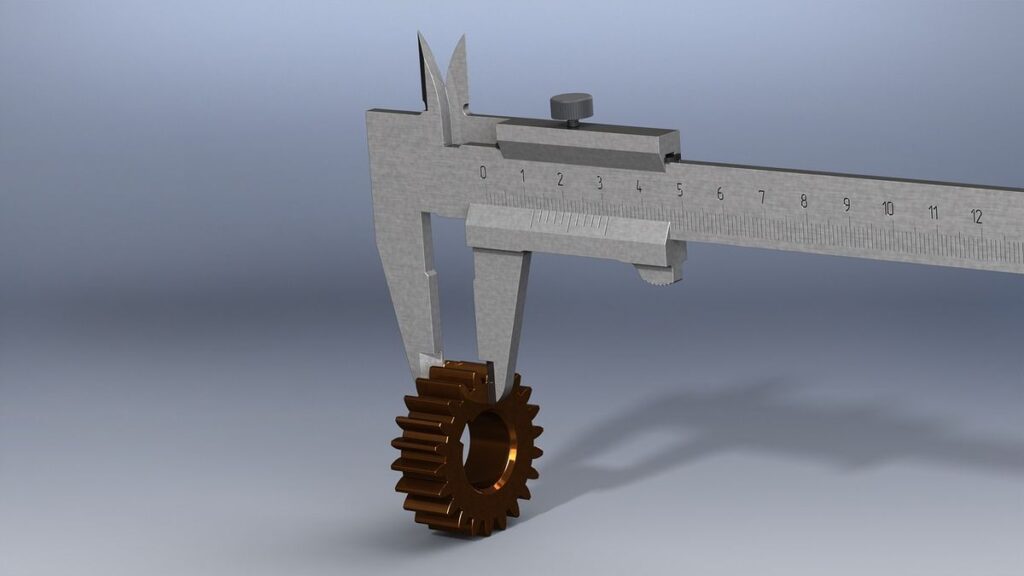

When it comes to woodworking and millwork, angles must be measured with precision to ensure the perfect fit and finish. Angle measuring tools come in various forms, from simple protractors to sophisticated digital angle finders that provide exact measurements in degrees.

- Protractors are the most basic tool for angle measurement, suitable for quick checks and educational purposes.

- Bevel gauges allow for the transfer of angles from plans to workpieces.

- Digital angle finders offer a high level of accuracy and can easily be read on a digital display.

Ensuring that angles are measured correctly is crucial in creating joints that fit seamlessly and in achieving the desired aesthetic of the final product.

Cross-Checking Dimensions

Unleash precision in millwork estimation with cutting-edge software

In the realm of millwork estimation, precision is paramount. Cutting-edge software elevates the accuracy of quantity takeoffs and material estimations to new heights. These tools are designed to streamline the estimation process, from initial measurements to final costings.

Software solutions range from traditional Excel spreadsheets, with their versatile formulas and customizable macros, to more advanced systems that offer project management capabilities and integration. The choice of software should be informed by factors such as project size, complexity, and budget constraints.

Embracing digital tools not only enhances efficiency but also ensures greater accuracy in millwork projects.

While manual methods have their place, the trend is shifting towards digital solutions for their added efficiency and precision. Here’s a quick overview of the pros and cons of using estimating software:

- Can be expensive

- Requires training to use effectively

However, the investment in such software can pay dividends in the long run, as it helps to avoid costly errors and saves time on repetitive tasks.

Enhancements with Deltek Vantagepoint 6.5

Measuring Tools

In the realm of precision woodworking and millwork manufacturing, the selection and application of measuring tools are pivotal. These tools range from basic hand tools to sophisticated electronic devices, each serving a specific purpose in the fabrication process.

- Oscilloscopes and Spectrum Analyzers are used for detailed electronic measurements.

- Multimeters and Analyzers provide versatile functionality for various testing needs.

- For prototyping, Soldering Stations and Breadboards are indispensable.

- During Production & Repair, Microscopes and 3D Printers play a crucial role.

The integration of these tools into the manufacturing workflow not only streamlines the process but also ensures the highest level of accuracy and quality in the final product. Real-time monitoring and predictive maintenance are key factors in enhancing manufacturing efficiency.

The table below summarizes the key measuring tools and their primary uses in the woodworking and millwork industry:

Prototyping

In the realm of woodworking and millwork manufacturing, prototyping is a critical phase that bridges the gap between design and full-scale production. It allows for the testing of design concepts, materials, and construction methods before committing to large-scale manufacturing. Prototyping can range from simple models to detailed, functional units that mimic the final product.

The process often involves a series of steps:

- Sketching the initial design outline, focusing on silhouette and general proportions.

- Adding details such as folds, strings, and other decorative elements, considering the fabric and texture.

- Translating the sketch into a digital model using software like KiCad, which guides users through the schematic entry to the nuances of PCB design.

- Building circuits on a breadboard and connecting to hardware like Arduino for programming and testing.

Prototyping not only validates the design but also uncovers potential issues that can be addressed before production, ensuring a smoother transition to the manufacturing phase.

The use of software tools in prototyping, such as KiCad for PCB design, streamlines the process and enhances accuracy. These tools provide clear examples and guidance, making it easier for designers to replicate circuits flawlessly and test their functionality before moving on to the next stage.

Production & Repair

In the realm of woodworking and millwork manufacturing, the production and repair stages are critical for ensuring the longevity and quality of the final product. Deltek Vantagepoint 6.5 enhances these processes by integrating advanced tools that streamline operations and improve precision.

The integration of digital manufacturing solutions with traditional woodworking techniques marks a significant advancement in the industry. It allows for more efficient production cycles and higher quality repairs.

The following list highlights key components of Deltek Vantagepoint 6.5 that are instrumental in production and repair:

- DriveWorks Implementation and Extensions

- Tacton Implementation

- Millwork Detailing and Cabinet Drafting

- Woodwork CAD Drafting

- Estimation & Quantity Takeoffs

- Engineering Design including 3D CAD Modeling

Each of these elements plays a vital role in the production lifecycle, from initial design to final assembly, and in the maintenance of millwork products. The software’s capabilities in 3D CAD modeling and estimation are particularly beneficial for custom designs and replacements, ensuring that every detail is accounted for with the utmost accuracy.

Importance of Precision and Accuracy in Woodworking/Millwork Manufacturing

3D Visualization

Three-dimensional visualization tools are revolutionizing the woodworking and millwork manufacturing industry. By enabling the creation and interaction with 3D models of projects, these tools provide estimators with a deeper insight into the structures and components they are working with. This leap in technology not only boosts the precision of measurements but also streamlines communication among project stakeholders.

The process of 3D visualization typically involves several steps:

- Obtain a digital representation of the project.

- Analyze the model for structural integrity and design efficiency.

- Use the model to simulate real-world conditions and assess potential outcomes.

- Refine the model based on feedback and simulations to ensure optimal design.

By meticulously crafting a 3D model, professionals can preemptively identify and address potential issues, leading to a more efficient and error-free production process.

The advancements in 3D visualization are akin to the progress seen in other fields where accurate measurements are vital. For instance, in the realm of prescription eyewear, accurate refraction measurement is essential for a comfortable and clear visual experience. Just as technology is pivotal in achieving optimal vision correction, it is equally crucial in the precise crafting of woodwork and millwork.

Automation using Specialized Tools like High-End Sales Configurators

The integration of automation in woodworking and millwork manufacturing is revolutionizing the industry. High-end sales configurators are at the forefront of this transformation, offering a seamless and efficient approach to quantity takeoff and material estimates.

Streamlined Estimation: These advanced tools are designed to automate the estimation process, providing highly accurate estimates that are tailored to the specific needs of each project. By reducing manual data entry, they significantly lower the risk of human error and enhance overall productivity.

Ease of Configuration: The user-friendly interfaces of these configurators allow for quick and easy adjustments, making them accessible to a wide range of users. For more complex requirements, they offer the capability to execute stored procedures or SQL scripts, ensuring a high degree of customization and control.

Here’s a brief overview of the benefits:

- Reduction in time and errors during the estimation phase

- Enhanced communication with project stakeholders through 3D visualization

- Customizable workflows that adapt to unique business requirements

Embracing these tools not only streamlines operations but also provides a competitive edge in the market.

In the world of woodworking and millwork manufacturing, precision and accuracy are not just desirable, they are essential. Every cut, joint, and finish must be executed with the utmost attention to detail to ensure the integrity and beauty of the final product. To achieve this level of craftsmanship, professionals rely on advanced tools and techniques. Discover how our OPTIGRID system can revolutionize your workflow and elevate the quality of your work. Visit our website to learn more and sign in to experience the difference that precision can make.

Conclusion

In conclusion, mastering precision in segment height measurement is crucial for ensuring accuracy and efficiency in various industries, especially in woodworking and millwork manufacturing. Utilizing a combination of accurate measuring tools such as laser measures, tape measures, levels, and angle measuring tools, along with cutting-edge software for millwork estimation, can significantly enhance the quality of projects. The integration of 3D visualization tools and automation using specialized tools further elevates the precision and efficiency of the estimation process. By prioritizing precision and accuracy in measurement techniques, professionals can streamline their workflows, avoid material wastage, and deliver high-quality results within budget and time constraints.

Frequently Asked Questions

What are the benefits of using laser measures in woodworking and millwork manufacturing?

Laser measures provide high accuracy for long distances and hard-to-reach areas, ensuring precise measurements in woodworking projects.

How can tape measures contribute to precision in millwork estimation?

Tape measures are essential for shorter distances, allowing precise measurements for accurate millwork estimation and manufacturing.

Why is cross-checking dimensions important in woodworking projects?

Cross-checking dimensions ensures accuracy and consistency in measurements, reducing errors and improving the overall quality of woodworking projects.

What are the key features of Deltek Vantagepoint 6.5 that enhance woodworking and millwork manufacturing processes?

Deltek Vantagepoint 6.5 offers improvements in measuring tools, prototyping capabilities, and production & repair functionalities, enhancing efficiency and precision in woodworking and millwork manufacturing.

How does 3D visualization contribute to accuracy in millwork estimation?

Three-dimensional visualization tools enhance accuracy by providing a clearer understanding of project structures and components, enabling better communication and precise estimation in millwork projects.

What role do high-end sales configurators play in automating millwork manufacturing processes?

High-end sales configurators automate the calculation of dimensions, areas, volumes, and accessory requirements, streamlining the millwork manufacturing process and ensuring precision in product fabrication.

I am a seasoned software engineer with over two decades of experience and a deep-rooted background in the optical industry, thanks to a family business. Driven by a passion for developing impactful software solutions, I pride myself on being a dedicated problem solver who strives to transform challenges into opportunities for innovation.